Introduction

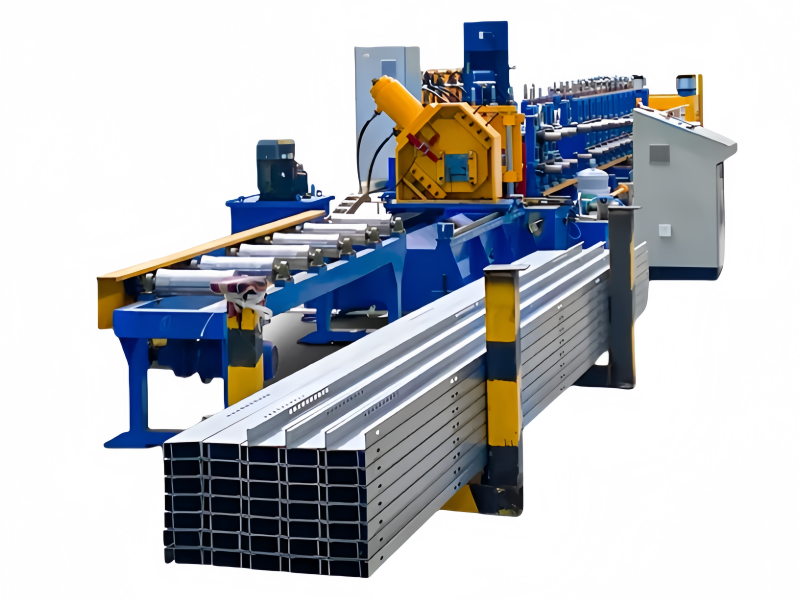

The Cable Tray Roll Forming Machine is a state-of-the-art manufacturing solution designed to produce high-quality cable trays with precision, speed, and efficiency. Unlike traditional bending machines, this advanced equipment allows for continuous, automated production, ensuring consistent quality while reducing labor costs and material waste.

Whether you’re supplying cable trays for data centers, industrial plants, or commercial buildings, our roll forming machine delivers superior performance and reliability.

Why Choose Our Cable Tray Roll Forming Machine?

✅ High Efficiency & Automation

- Continuous production with speeds up to 25 meters per minute

- PLC-controlled operation for precise, repeatable results

- Automatic cutting & stacking for streamlined workflow

✅ Precision Engineering

- ±1mm tolerance for perfect fit and installation

- Adjustable rollers for different cable tray dimensions

- Consistent quality across large production runs

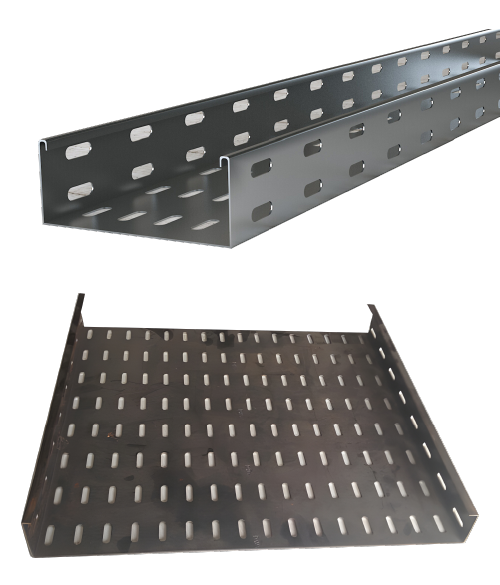

✅ Versatile Production Capabilities

- Multiple cable tray types: ladder, perforated, channel, and wire mesh

- Wide size range:

- Bottom width: 100mm to 400mm (adjustable in 1mm increments)

- Waist height: 50mm, 100mm, or 150mm

- Material thickness: 0.5mm to 1.5mm

✅ Durable & Low-Maintenance

- Hardened steel rollers for long-lasting performance

- Automatic lubrication system to minimize wear

- Heavy-duty frame for stable operation

Technical Specifications

| Parameter | Specifications |

|---|---|

| Bottom Width | 100mm, 150mm, 200mm, 250mm, 300mm, 350mm, 400mm |

| Waist Height | 50mm, 100mm, 150mm |

| Thickness | 0.5mm – 1.5mm |

| Production Speed | Up to 25m/min |

| Control System | PLC with touchscreen interface |

Applications of Cable Trays Made with Our Machine

🏢 Commercial Buildings – Organized cable management for offices, malls, and hospitals

⚡ Industrial Plants – Durable cable support for heavy-duty environments

📊 Data Centers – Efficient routing for high-density server cabling

🏗 Infrastructure Projects – Reliable cable organization for airports, metro systems, and power plants

Comparison: Traditional Bending vs. Roll Forming

| Feature | Traditional Bending | Our Roll Forming Machine |

|---|---|---|

| Production Speed | Slow & labor-intensive | Fast & automated (up to 25m/min) |

| Precision | Manual adjustments needed | Consistent ±1mm tolerance |

| Material Waste | High due to cutting errors | Minimal scrap, optimized usage |

| Labor Cost | Requires skilled workers | Reduced dependency on operators |

Why Upgrade to a Roll Forming Machine?

✔ Higher output with less manual work

✔ Better quality control with automated measurements

✔ Lower production costs due to reduced waste

✔ Flexible manufacturing for custom cable tray sizes

Get Your Cable Tray Production Solution Today!

Upgrade your manufacturing process with our high-performance Cable Tray Roll Forming Machine.

📞 Contact us now for a free quote & consultation!

📧 Email: sales@xyformingmachine.com

🌐 Website: www.xyformingmachine.com

Meta Description:

Looking for an efficient Cable Tray Roll Forming Machine? Our automated solution produces high-quality cable trays with precision and speed. Get a quote today!

Keywords:

cable tray roll forming machine, cable tray production line, electrical raceway forming equipment, automated cable tray machine, metal roll forming system